As companies weigh the uncertainties of reshoring, tariffs, and rising labor costs, warehouse automation is moving forward—but not necessarily in the way some expected. Instead of billion-dollar automated facilities, many organizations are opting for smaller, more targeted deployments, especially during these uncertain times, according to Zebra Technologies executives Andre Luecht and Nicholas Wegman.

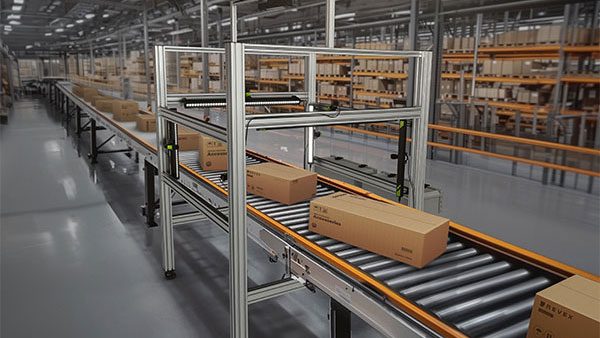

“If we are really finding ourselves in an environment where there is large-scale nearshoring or reshoring of labor … the answer would be automation,” says Luecht, global strategy lead, transportation, logistics and warehousing. “Because these sites do not exist, we’re talking about greenfield automation. And greenfield automation is something that would require automatic data capturing, automatic sortation, storage solutions, AMRs, et cetera.”

However, Luecht notes that most companies today are opting for a more measured approach. “We will see … a lot of retrofitting, greenfield automation. That’s a different type of automation. It would be a point-of-workflow automation.”

The reason? Time and cost. Many companies leasing warehouse space face short contract windows—often five years or less—which means major infrastructure investments don’t always make financial sense.

“Whatever you put into that place, if you don’t own it, can be paid back within five years,” Luecht asks. “Anything that exceeds two to three years is currently very, very difficult to find internal funding for … You usually talk about point and workflow optimization, not complete building optimization.”

OPEX over CAPEX

With rising interest rates and economic uncertainty, capital expenditures are harder to justify. Instead, Luecht says, many customers are exploring OPEX (operating expense) models or smaller-scale investments that deliver faster returns.

“There is a pressure to automate,” he notes. “Labor cost has increased significantly. We have gotten some feedback from some of our customers that in some areas it’s almost untenable.”

That has driven even more appetite for automation, just on a targeted scale. Luecht points to increasing demand for technologies that eliminate repetitive manual tasks and enhance visibility, including:

- Automated data capture using barcodes, smart cameras, and OCR.

- RFID tracking—especially source tagging at the manufacturing level.

- Smart camera systems capable of decoding 2D barcodes or QR codes.

“What can be automated will be automated,” Luecht says.

Smarter tech, smarter decisions

Nicholas Wegman, senior director, AI scientist, adds that Zebra’s focus is not just on hardware, but on connecting frontline workers and enabling intelligent automation across the supply chain. That includes software solutions that help retailers manage their two most important assets: people and inventory.

“Our software solution suite … helps with timekeeping and scheduling and communication … and then we’ve got software solutions that help with their inventory visibility, as well as our demand intelligence platform,” Wegman explains.

He acknowledges the surge in interest around artificial intelligence, but cautioned against the buzzword becoming a catch-all solution. In fact, Wegman notes that forms of artificial intelligence have been around for many years, dating back to things like computer vision, speech recognition, and predictive analytics.

The real challenge now, he says, is not deploying AI, but getting people to adopt and integrate it into their daily routines.

“There’s this long tail of AI adoption … You start to communicate with [users] about what they’re doing and how does that change your day-to-day work,” Wegman says.

The future is granular and real-time

Looking ahead, both executives see increasing demand for item-level, real-time visibility and contextual intelligence, especially as supply chains become more complex.

“People want real-time location, item-level scans and verification, over-the-road and [with] condition ideally—temperature, humidity maybe,” says Luecht. “There’s a lot more requirements on the track-and-trace side than we had in the past, and now we have the technology.”

Even last-mile logistics is undergoing transformation, with more intelligent rerouting and delivery visibility. “You can track your pizza like an Uber… but the question is, can I track my parcel the same way?” Luecht asks.

As automation continues to evolve, Luecht reminds that adoption is still early despite the industry hype. For companies weighing whether to act now or wait out uncertainty, Luecht has this advice: “If you’re already investing in smaller-scale automation today, you’ll be in a better position than your competitors tomorrow.”

SC

MR

More Warehouse Automation

- Targeted automation offers an entry into the new frontier

- Optimizing warehouse labor costs: 3 essential strategies

- Unlocking a digital transformation success story

- 6 Questions With … Christian Floerkemeier

- Embracing the EPC model for automated distribution and fulfillment projects

- More Warehouse Automation

Explore

Explore

Topics

Software & Technology News

- Employee versus enterprise AI adoption

- Uber Freight’s Val Marchevsky to deliver Keynote at NextGen Supply Chain Conference

- Trust the team, win the customer

- Breaking barriers in B2B forecast sharing: How sFTP automation is reshaping supply chain data exchange

- A conversation on the life sciences supply chain with DHL’s Jim Saponaro

- Data center growth driving new logistics opportunities

- More Software & Technology

Latest Software & Technology Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks